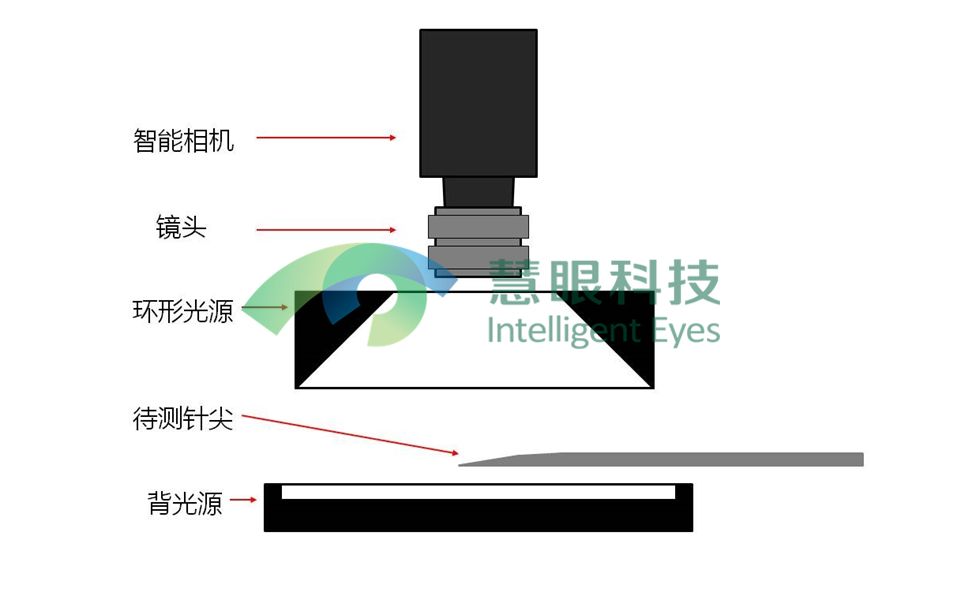

This equipment is mainly composed of camera, len and light. In this system, the main task is to obtain a clear tip contour for comparison with the set value. In the backlight mode, the light source is evenly illuminated from the back side of the object to be detected, and a high-definition tip contour can be obtained. In the ring light illumination mode, a non-directional, soft light suitable for a highly reflective object can be produced. According to the actual situation of the measured object and in order to prevent interference between the light sources, an illumination subsystem is designed which combines two kinds of light sources: backlight illumination and ring light illumination.

The tip of the needle enters the visual inspection area and triggers the camera to take photos regularly after the grinding process is completed. At the same time, the camera completes image processing and detection, and outputs corresponding detection signals to the PLC to process.

Disposable syringe tip appearance inspection system based on machine vision technology has been successfully put into the production line use. The running data shows that the system detects the time range (single "photograph+Process" total time) at 100-120ms, false detection rate no more than five thousandths.

The successful development of this project has solved the high cost of manual testing and high false detection rate. The problem is to ensure the quality of the product, greatly improve the production efficiency, and effectively reduce the management and production costs of the customer.

WeChat

Message

TOP

WeChat

Message

TOP

Sitemap Links Copyright Information Legal Notices

Copyright ? 2018 慧眼自動化科技(廣州)有限公司. All Rights Reserved 粵ICP備10005877號 Designed by Wanhu.